Article Title:

Analyzing the Effect of Temperature on Alloy Steel Forging Simulation Using Finite Element Simulation

Authors:

- DAME Alemayehu Efa,

- HIRPA G. Lemu

- ENDALKACHEW Mosisa Gutema

- MAHESH Gopal

Abstract:

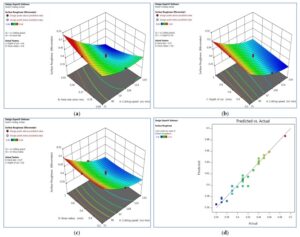

The goal of this research is to examine the influence of temperature affects the forging of a rectangular billet of AISI 4120 alloy steel using the 3D Deform version 11 software. The simulation was performed with 0.3 coefficient of friction on a metal forming (lubricated) process and the part is intended for application in aerospace and oil and gas industries. Three modules of deform software were defined to execute the simulation: pre-processing, simulation, and post-processing. The pre-processing in forging employed standard data— material selection, billet drawing, top and bottom dies design, meshing and simulation control. After 120 steps, the post-process estimation of deformation temperature, effective strain and stress, total velocity, and total displacement were obtained on the billet of material at temperatures of 800o C, 1000o C, and 1200° C. The results show that when forging temperatures climb, effective strain and stress decrease, total displacement and velocity decrease, and the final temperature increases.

Keywords: AISI 4120 alloy steel, Metal forming simulation, Open die forging process, Deform-3D, Inter-object, Plastic deformation.

Download Full Article Here: